The Carbon Cost of

Construction Materials

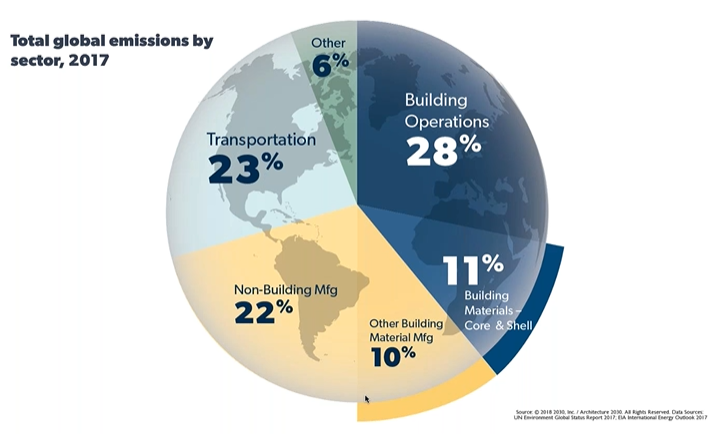

The built environment accounts for about 50% of total global greenhouse gas emissions. That’s a larger contribution than any other slice of our emissions pie. This makes it clear that the construction industry has huge potential, as well as responsibility, to reduce its carbon footprint. As our window for effective action on climate change is shrinking, we have no choice but to look to the statistics and make significant changes to the way we construct buildings.

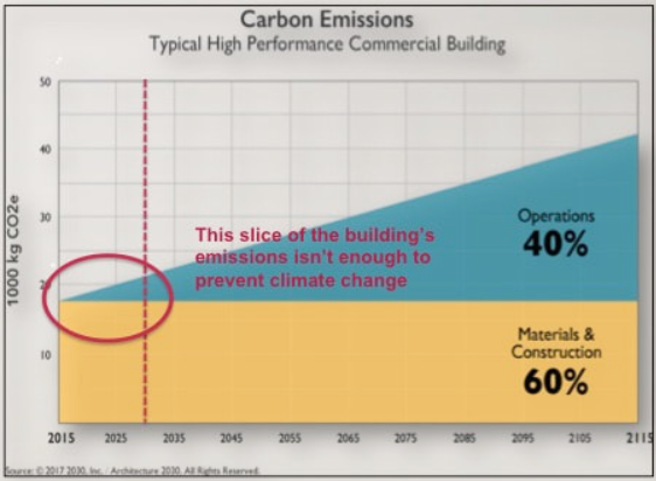

There are two kinds of carbon implicated in new construction. The first is operational carbon, which has been getting a lot of attention lately, with new energy efficiency standards and introduction of the BC Energy Step Code. Operational carbon (represented by the blue wedge on the image below) accounts for all the energy required for space heating/cooling, water heating, and ventilation of a building. When a building is first built, it has an operational carbon footprint of zero. Which each year it increases as the total energy required over the lifetime of the building adds up.

The other kind of carbon associated with construction is the embodied carbon (the yellow rectangle in the image below). It accounts for all the fossil fuels required for the extraction, processing, manufacture and transport of the materials we build with. Each construction material has a specific amount of carbon associated with its’ production: for example, concrete has a very high embodied carbon footprint, while wood products are quite low. Unlike operational carbon, all the embodied carbon associated with a construction project is already implicated as soon as the building is completed. To reduce our global carbon emissions on the time scale that is required, we must incorporate these up-front carbon costs into policy and decision making.

Take concrete. It’s a miracle material in terms of construction: durable, strong, affordable, familiar. Yet it accounts for up to 10% of total carbon emissions worldwide. That’s because carbon dioxide is released at two points during cement production; 40% from burning fossil fuels to heat the limestone to extremely high temperatures, and 60% from naturally occurring chemical reactions during processing. It’s not that we need to stop using the material altogether – it’s just time to use it intelligently and sparingly, and really take advantage of its structural properties rather than using it without regard.

Other materials that have high embodied carbon are foam insulation products. This includes materials like XPS rigid foam and spray foam. Although they perform incredibly well in terms of R-value per square inch, the payoff is that they have high up-front carbon costs. When making decisions for material choices in a building, it’s important to strike a balance –a foam and concrete ICF foundation may make the most sense for the site, but to counter the high embodied carbon, wood framing and cellulose insulation could be used for the above-ground floors.

So what materials are the best to use? Any that are made from natural sources or materials diverted from the waste stream. That includes sustainably harvested timber, wood fiber board, cork, cellulose insulation, waste textiles etc. There are also exciting initiatives coming out such as Carbon Cure, a Canadian-based company that has figured out a way to inject and store C02 in concrete in order to create a carbon neutral concrete. They sell their tech to concrete factories who can easily retrofit their operations.

Drastically reducing the up-front carbon costs of new construction is not hard. Many low-carbon materials are already widely available, familiar, and come at no cost premium. And as another benefit, materials with low carbon footprints also tend to be healthier for occupants and have less harmful ecosystem impacts. It’s a win-win-win! With the necessity to act fast on carbon emissions looming large, the only way forward for the construction industry is to address both energy efficiency and embodied carbon.